Machining

When DFC first started rebuilding engines we utilized local machine shops to do our machining of blocks, crankshafts and cylinder heads. This showed us the capacity and limitations of general machine shops that do not specialize in just a few types of engines. They all lacked the application specific cutters and tooling to supply repeatable results, and were unaware of common failure areas to pay extra attention to. As most machine shops offer a 1 year 20,000km or more uncommon unlimited mileage warranty, which is typically parts only, the service life of cylinder heads in particular are only to make the warranty period. This means that most shops will reuse your valves and springs, not replace the seats and only replace individual guides as needed or worse yet for diesels, install bronze guide liners that WILL prematurely fail.

Once realizing that this was commonplace in the industry, DFC committed to purchasing brand new cutting edge Rottler equipment and began remanufacturing everything in house. With the capabilities that this equipment brings to the industry (combined with the best diesel parts and accessories in Edmonton), we were able to bring a level of precision machining to the diesel industry unrivaled by any machine shop and/or remanufacturer in Canada.

ROTTLER F69ATC

The Rottler F69 ATC was chosen for its speed and consistency and allows us to inspect blocks faster and more accurately for cylinder locations and deck heights than any conventional machine shop out there. This is possible as the 4th axis in the machine locates the block with application specific main line and cam line locators. This repeatable process base all our measurements off these two locations and utilizes a Reninshaw probing system that measures the deck heights and cylinder locations to within 0.0001” (one tenth of a thousandth inch). With these measurements we can easily observe if the block is warped or if a previous machine shops equipment was inaccurate in machining. Once blueprinted the F69 ATC bores and surfaces in the same fixture, using the same measurements recorded, allowing us to bore perfectly perpendicular to the cylinder deck.

ROTTLER H75A

DFC received the first automated hone from Rottler in existence and are proud to showcase its abilities with every engine we remanufacture. With a CNC controlled operating system it allows every engine to have the exact same cross hatch angle in every cylinder and with a load sensing honing head gets every bore within 0.0002” (two tenths of a thousandth inch) for taper and out of round with ease. Finishing off with a pre-programmed plateau mode gives our engines the same level of quality found when built in the OE manufacturing plants. These finishes are QC checked using a profillometer ensuring the proper RA surface finish for proper ring seating and longevity.

ROTTLER SG10X

Another precision piece of equipment and first of its kind, the SG10X allows unsupervised operation of core drill reaming, seat pocket and seat angle cutting. The rigidity of the spindle head and live pilot design gives mirror like seat finishes that are repeatedly cut to the same depth. This allows us to maintain strict quality control and have identical results on every cylinder head we remanufacture. Its automatic functions allow more production to be done and being CNC controlled gives repeatable results each time it is used.

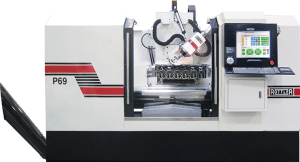

ROTTLER P69

A welcome addition to our lineup of precision Rottler equipment the P69 is the first and only one purchased in Canada. The P69 allows fast and precise digitizing and cutting of head ports and allows reverse engineering of existing port designs through the use of a Reninshaw probe. The ability to design intakes and produce custom parts as well as cut O-rings in cylinder heads makes this machine extremely versatile. With patented technology the P69 raises the bar for precision engine machining equipment and further demonstrates our desire of bringing the most advanced machining equipment to the business.

ROTTLER SG9MTS

Finishing off our lineup of the most advanced automotive machining equipment in Canada is the SG9MTS seat and guide machine. The SG9MTS has all the same design features of the SG10X but in a manual version. The live UNIPILOT design keeps concentricity of seat cutting to above industry standard and the production fixture combined with programmable cutter heights and speeds allows for precision machining with production speeds. Perfect sealing of valves is possible each time, every time.